Company History

2020

In order to take a further step in the direction of automated production, complex sheet metal parts are now also bent fully automatically with the aid of a modular canting robot.

The resulting increased productivity and the accelerated work processes also increase the quality of the sheet metal parts manufactured in production.

2019

2019

2018

At the beginning of 2018, construction work started on an additional production hall on a production area of around 2,500 m².

When the hall extension was completed in November 2018, all production departments and workplaces were restructured and geared towards the future.

2018

At the beginning of 2018, construction work started on an additional production hall on a production area of around 2,500 m².

When the hall extension was completed in November 2018, all production departments and workplaces were restructured and geared towards the future.

2016

With the purchase of two systems for laser welding, the welding processes in our own production were further optimized and raised to a new technological and qualitative level.

The advantages of laser welding now enable the processing of welding components that previously could not be welded in the conventional way.

2016

With the purchase of two systems for laser welding, the welding processes in our own production were further optimized and raised to a new technological and qualitative level.

The advantages of laser welding now enable the processing of welding components that previously could not be welded in the conventional way.

2010

With the entry of the son Boris Malsy into the company and the associated expansion of the management in the following year, the family company is now in the second generation.

2010

2008

As a further milestone in the company’s history, the decision is made to purchase the world’s fastest fully automated punching machine.

KM Blechverarbeitung GmbH is now able to produce sheet metal parts unmanned 24 hours a day, thus entering a new dimension in automation.

2008

2002

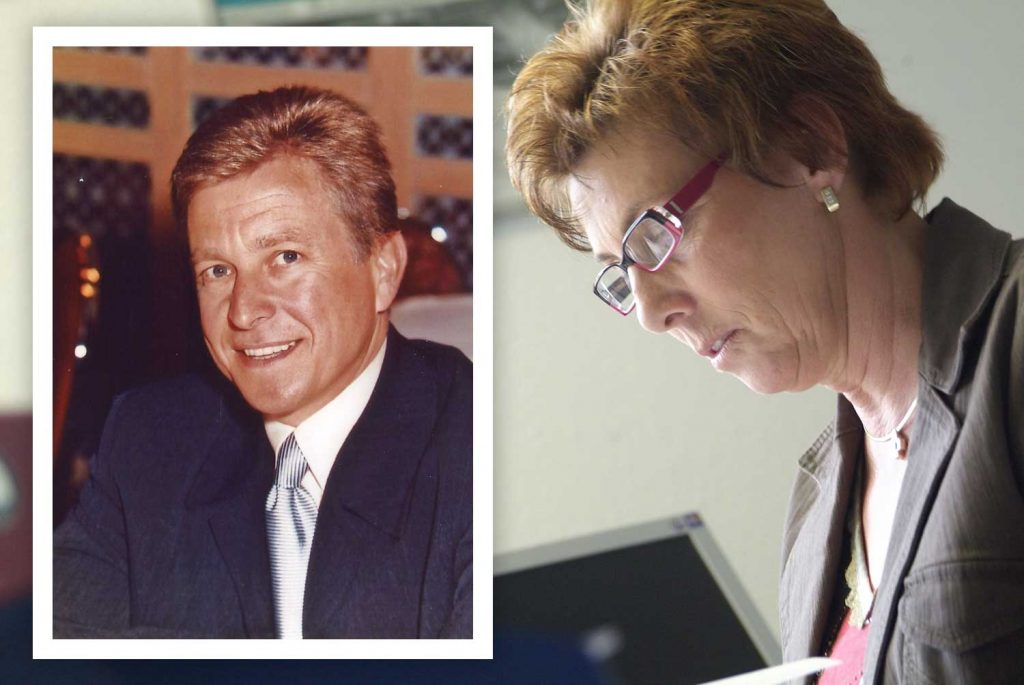

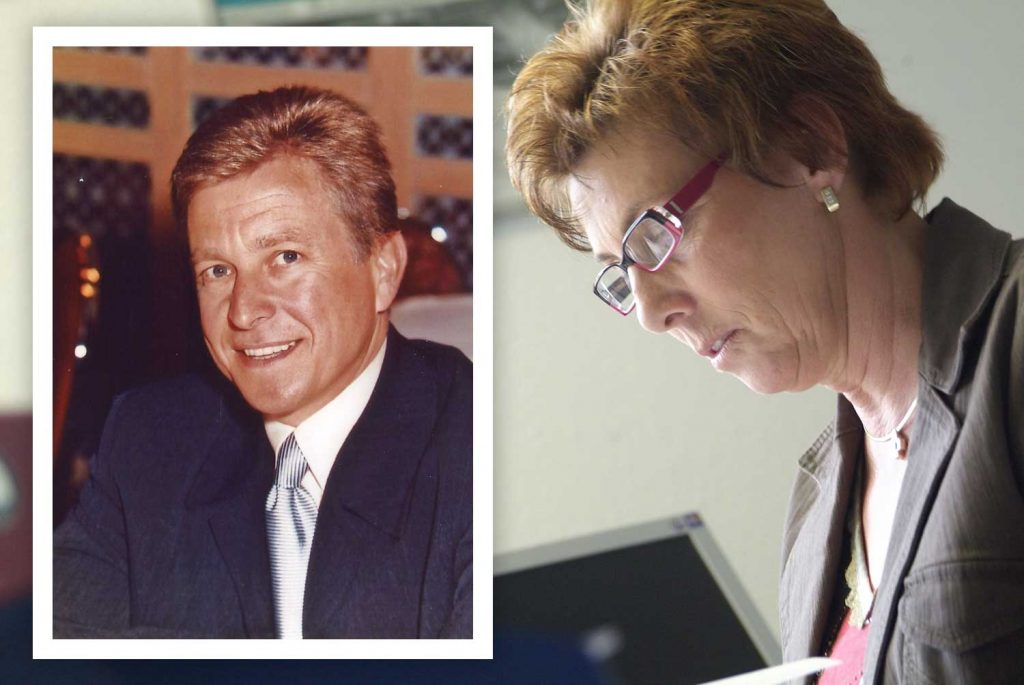

In December, the managing director and company founder Klaus Malsy dies after a serious illness.

With the great support of the long-standing employees, his wife Edith Malsy decides to take over the management and continue the company.

2002

In December, the managing director and company founder Klaus Malsy dies after a serious illness.

With the great support of the long-standing employees, his wife Edith Malsy decides to take over the management and continue the company.

2001

Due to further expansion, Hall 3 has now been built. With the completion, the production area was expanded to over 2,000 m².

2001

Due to further expansion, Hall 3 has now been built. With the completion, the production area was expanded to over 2,000 m².

1999

In addition to our laser machine, we invested in a punch-laser combination machine from Trumpf.

1999

1998

The company’s workforce, which has now grown to 20 employees, justifies the expansion of the production area with the second production hall towards the motorway to 1,500 m².

1998

The company’s workforce, which has now grown to 20 employees, justifies the expansion of the production area with the second production hall towards the motorway to 1,500 m².

1995

After a steadily growing customer base and the associated relocations of production, the company finally moved to its own newly built production hall with administration building at Sandborn 18.

With the move to the new production hall, one of the first laser cutting systems in the Rhine-Main area is installed, which gives the company a technological edge in the processing of sheet metal.

1995

1990

Since there is no longer enough space in the existing premises, a move to an old barn takes place in the center of Froschhausen.

At the same time, investments are made in a CNC-controlled punching machine, which opens up new production possibilities for Klaus Malsy. The first employees are hired in the following months.

1990

Since there is no longer enough space in the existing premises, a move to an old barn takes place in the center of Froschhausen.

At the same time, investments are made in a CNC-controlled punching machine, which opens up new production possibilities for Klaus Malsy. The first employees are hired in the following months.

1989

1989

Company History

1989

1989

1990

Since there is no longer enough space in the existing premises, a move to an old barn takes place in the center of Froschhausen.

At the same time, investments are made in a CNC-controlled punching machine, which opens up new production possibilities for Klaus Malsy. The first employees are hired in the following months.

1990

Since there is no longer enough space in the existing premises, a move to an old barn takes place in the center of Froschhausen.

At the same time, investments are made in a CNC-controlled punching machine, which opens up new production possibilities for Klaus Malsy. The first employees are hired in the following months.

1995

After a steadily growing customer base and the associated relocations of production, the company finally moved to its own newly built production hall with administration building at Sandborn 18.

With the move to the new production hall, one of the first laser cutting systems in the Rhine-Main area is installed, which gives the company a technological edge in the processing of sheet metal.

1995

1998

The company’s workforce, which has now grown to 20 employees, justifies the expansion of the production area with the second production hall towards the motorway to 1,500 m².

1998

The company’s workforce, which has now grown to 20 employees, justifies the expansion of the production area with the second production hall towards the motorway to 1,500 m².

2001

Due to further expansion, Hall 3 has now been built. With the completion, the production area was expanded to over 2,000 m².

2001

Due to further expansion, Hall 3 has now been built. With the completion, the production area was expanded to over 2,000 m².

2002

In December, the managing director and company founder Klaus Malsy dies after a serious illness.

With the great support of the long-standing employees, his wife Edith Malsy decides to take over the management and continue the company.

2002

In December, the managing director and company founder Klaus Malsy dies after a serious illness.

With the great support of the long-standing employees, his wife Edith Malsy decides to take over the management and continue the company.

2008

As a further milestone in the company’s history, the decision is made to purchase the world’s fastest fully automated punching machine.

KM Blechverarbeitung GmbH is now able to produce sheet metal parts unmanned 24 hours a day, thus entering a new dimension in automation.

2008

2010

With the entry of the son Boris Malsy into the company and the associated expansion of the management in the following year, the family company is now in the second generation.

2010

2016

With the purchase of two systems for laser welding, the welding processes in our own production were further optimized and raised to a new technological and qualitative level.

The advantages of laser welding now enable the processing of welding components that previously could not be welded in the conventional way.

2016

With the purchase of two systems for laser welding, the welding processes in our own production were further optimized and raised to a new technological and qualitative level.

The advantages of laser welding now enable the processing of welding components that previously could not be welded in the conventional way.

2018

At the beginning of 2018, construction work started on an additional production hall on a production area of around 2,500 m².

When the hall extension was completed in November 2018, all production departments and workplaces were restructured and geared towards the future.

2018

At the beginning of 2018, construction work started on an additional production hall on a production area of around 2,500 m².

When the hall extension was completed in November 2018, all production departments and workplaces were restructured and geared towards the future.