Welding

Welding with the most advanced technologies

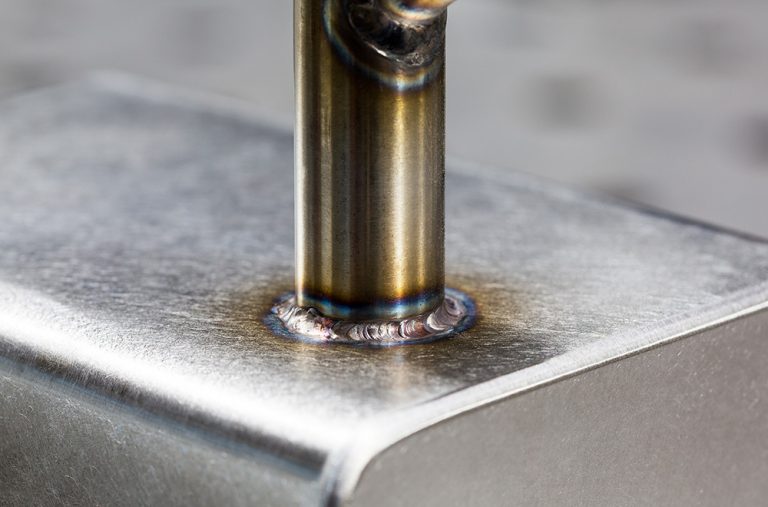

Welding is a core skill in sheet metal processing: it doesn’t matter whether WIG, MT, MAG, stud welding, point welding or laser welding, we can offer the optimum welding process for your component in all materials.

With our welding table, which is equipped with a 3D clamping system, we are able to manufacture the most complex welding groups at the highest precision and quality in our workspaces.

Our employees undergo regular welding tests so that we can ensure a permanently high welding quality for all components in our manufacturing.

We have been able to achieve a very high level of competence over the last 35 years for demanding stainless steel parts in particular.

Joining by fusion

Welding is a versatile and essential manufacturing process used in a wide range of industries. At KM Blechbearbeitung, we pride ourselves on our perfect command of this key process and our ability to provide our customers with high-quality welding services.

What is welding?

Welding is a joining process in which two or more workpieces are fused together by heat, pressure, light, or a combination of all. This process creates a permanent, strong bond that is essential in many applications. Welding is not only a technical process, but also an art form that requires precision and skill.

Our expertise in welding

Klaus Malsy Blechbearbeitung GmbH has a highly qualified team of welders with the current welder examination certificates and the latest welding equipment. Our professionals specialize in using a wide range of welding techniques, including arc, MIG and TIG welding, to ensure that we can meet our customers’ specific requirements. We are proud of our certified welders, who not only have the technical knowledge, but also the hands-on experience to successfully complete even the most challenging projects.

Quality and precision

At KM Blechbearbeitung GmbH, we place the utmost importance on quality and precision in every step of the welding process. From the selection of the best materials to the careful preparation of the workpieces and the actual welding work, nothing is left to chance at our company. Our quality control team monitors the entire process to ensure that each sheet metal assembly meets our high standards. In addition, our employees are regularly qualified and monitored based on welder examinations to meet specific requirements.

Versatile applications

Our welding services are used in a wide range of applications. We have welding experience in sheet metal assemblies in industries such as medical, automotive & food, mechanical, plant, petrochemical and many others. Regardless of the industry or project scope, we provide customized solutions to meet our customers’ specific requirements for sheet metal parts and assemblies.

Customized Solutions

At KM Blechbearbeitung, we understand that no two projects are the same. That’s why we offer custom solutions tailored to meet our customers’ exact needs. Whether it’s one-of-a-kind fabrications or high-volume production, our experts are available to provide advice and assistance to make your project a success with our help. We work closely with you to ensure that your quality standards and specifications are implemented to the best of our ability in the metal assembly we build.

Sustainability and Innovation

We are actively committed to sustainability and environmental protection in our work. By using the latest technologies and environmentally friendly materials, we help minimize the impact of our welding processes on the environment. Our ongoing investment in research and development allows us to utilize innovative welding techniques, such as laser welding, and to always offer the latest solutions to our customers.

Contact us

When you need welding work of the highest quality, we are your reliable partner. Klaus Malsy Blechbearbeitung stands for reliability, precision, sustainability and commitment in sheet metal processing. Feel free to contact us to learn more about our welding services.

Welding process

- WIG Welding

- MIG Welding

- MAG Welding

- Point Welding

- Stud Welding

- Laser Welding

Showroom

Take a look at our finished products